Chưa có sản phẩm trong giỏ hàng.

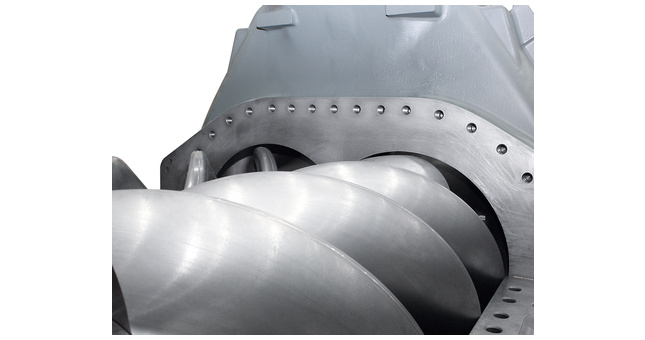

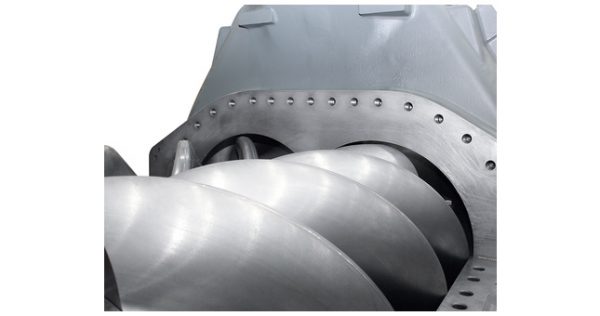

MÁY NÉN VÍT KHÔNG DẦU BỘ VRA

Liên Hệ

CÔNG TY CP TƯ VẤN VÀ ĐẦU TƯ D&H

Địa chỉ: Số 208 Đường Võ Chí Công, Phường Xuân La, Quận Tây Hồ, Thành Phố Hà Nội.

Số điện thoại: 0904.490.660 / 0967.240.616

Email: hungthanh@dautudh.vn – huyenle@dautudh.vn

Website: dautudh.vn

Đặt mua MÁY NÉN VÍT KHÔNG DẦU BỘ VRA

MÁY NÉN VÍT KHÔNG DẦU BỘ VRA

Hãy là người đầu tiên nhận xét “MÁY NÉN VÍT KHÔNG DẦU BỘ VRA”